Application these are vertically sliding gates used for isolation control of water flowing in and out of a closed conduit orifice for seating and or unseating water head application.

Slide gate valve specification.

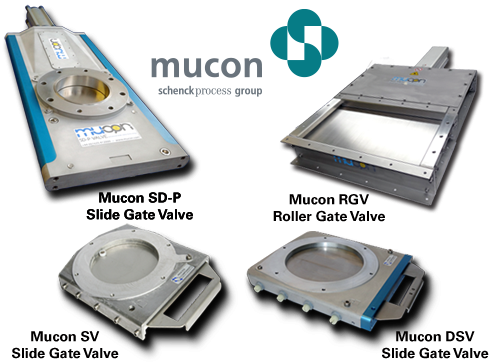

Either way our bulk material slide gate components are made with the same commitment to quality and durability found.

The seal shall be attached to the invert member or the bottom of the slide and it 11000 3.

Ss 250 stainless steel slide gate.

Valve seats and seals shall be effective throughout the pressure class at the design temperatures specified.

A 250 aluminum slide gate.

Vortex valves serve many industries including chemical cement coal food.

Jash offers these gates completely made from fiber reinforced plastic frp without any carbon steel internal reinforcements eliminates two different co efficient of thermal expansion of these different.

Vortex slide gates are designed and engineered with two main principals in mind.

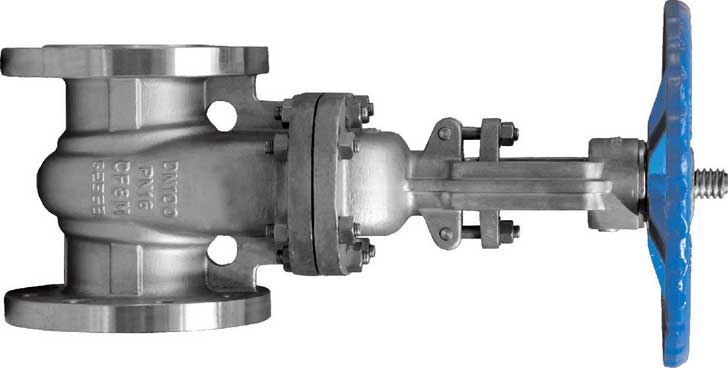

Gate valves and knife valves are linear motion valves in which a flat closure element slides into the media stream to shut off flow.

Heavy duty cast slide gates.

3 6 manual valve operators.

Extend the service life of the valve and 2.

All upward opening gates shall be provided with a resilient seal to seal the bottom portion of the gate.

B valve pressure class ratings shall be in accordance with ansi b16 34 api specification 6a or api specification 6d.

The slide gate valve helps control gravity batch unloading when handling dry free flowing materials.

Unique parallel slide forged cage unit design comprises all operating parts of the slide discs.

We offer them as permanent fixtures on gravity feeder systems or as maintenance valves used to isolate components for service.

Gate valves also known as knife valves or slide valves are linear motion valves in which a flat closure element slides into the flow stream to provide shut off.

Find gate valves on globalspec by specifications.

Specification figure f215 sf bonnetless slide gate valve 1000 kpa 150 psi design for 1000 kpa 150 psi cwp mss sp81 face to face dimension with flanges drilled and tapped to asme b16 5 150 as 2129 or din pn10 with machined raised gasket faces.

Stronger leakproof bolted body bonnet joint ensures joint tightness with a higher bolting torque.

For additional help in specifying a gate for your project we welcome your call to our design and specification support line 800 445 8457.

Valve body shall be fully fabricated from heavy gauge.

Designed to asme b16 34.

They are one of the most common valves used.

The seat seals shall extend to accommodate the 1 1 2 x the height of the slide when the slide is in the fully closed or fully opened position.

Ideal for handling dry bulk material in gravity flow dilute phase or dense phase pneumatic conveying applications.